Log in

Search

Latest topics

» Fox .35 Modifications by Onelife Today at 6:47 pm

» Happy Anzac Day!

by 706jim Today at 6:44 pm

» Project Cox .049 r/c & Citabrian Champion

by MauricioB Today at 4:08 pm

» Jim Walkers FireBee - This is going to be fun

by rsv1cox Today at 3:56 pm

» Revivng Some Childhood Classics

by rsv1cox Today at 7:17 am

» Introducing our Cox .049 TD Engines

by getback Today at 6:20 am

» Roddie's flat-bottomed boat..

by Levent Suberk Today at 12:23 am

» Cox powered jet-pump for model Sprint Boat

by roddie Yesterday at 10:25 pm

» Micro Draco Gets to Fly on a Beautiful Morning.

by rdw777 Yesterday at 8:15 pm

» Jim Walker Firebaby

by rdw777 Yesterday at 8:06 pm

» Hydro-bat by Vic Smeed: engine probs

by GallopingGhostler Yesterday at 5:12 pm

» Roddie-Rigger.. a 2005 original design

by roddie Yesterday at 3:39 pm

Cox Engine of The Month

Oriental ARF assembly

Page 2 of 5

Page 2 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Rusty / Ian , Is that hinge sanding block made of ply ? I really like the way those hinges look and gap less . I have plenty of those hinges and would like to use them on my larger models . Thanks Eric

getback- Top Poster

Posts : 10114

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: Oriental ARF assembly

Re: Oriental ARF assembly

getback wrote:Rusty / Ian , Is that hinge sanding block made of ply ? I really like the way those hinges look and gap less . I have plenty of those hinges and would like to use them on my larger models . Thanks Eric

Made from scrap pieces of balsa. Cyano glued together.

ian1954- Diamond Member

- Posts : 2688

Join date : 2011-11-16

Age : 69

Location : England

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Thanks Ian , Eric

getback- Top Poster

Posts : 10114

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: Oriental ARF assembly

Re: Oriental ARF assembly

One thing i should mention for anyone who has never installed pin hinges. They must be perfectly aligned with each other to prevent binding.

Use a piece of music wire that is exactly half as thick as the edge of the flap as a center guide. Lay it against the flap and draw a line along the full length of the flap. All hinge slots should be cut along this line.

Rusty

EDIT: I just fixed a confusing sentence in my earlier post. It now reads as follows:

"Leave the TE of the wing flat with only hinge slots and no recesses."

Use a piece of music wire that is exactly half as thick as the edge of the flap as a center guide. Lay it against the flap and draw a line along the full length of the flap. All hinge slots should be cut along this line.

Rusty

EDIT: I just fixed a confusing sentence in my earlier post. It now reads as follows:

"Leave the TE of the wing flat with only hinge slots and no recesses."

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Oriental ARF assembly

Re: Oriental ARF assembly

ian1954 wrote:getback wrote:Rusty / Ian , Is that hinge sanding block made of ply ? I really like the way those hinges look and gap less . I have plenty of those hinges and would like to use them on my larger models . Thanks Eric

Made from scrap pieces of balsa. Cyano glued together.

If you're scratch-building a wing with external spars, you could use a similar tool made to the width/depth of your spar to cut all the notches in a rib-stack too. Another use could be for cutting rib-stations into L/E and T/E stock. Make a T-block to fit in the first slot, to gage the location of the next slot to be cut.. then cut them all without having to mark/measure each one.

Re: Oriental ARF assembly

Re: Oriental ARF assembly

I bet when it's quiet, you can hear the wheels turning in Roddie's head.

A good rib slot cutter might be made from a cut down hacksaw or jigsaw blade with the right width kerf.

All I did today is mark the locations of where the wing needs to seat. I think some modeling clay might help me find the right size and dimensions of the center mounting sheet. I need to go over to SH and search out info on mounting wings in full fuse planes. This is my first.

Rusty

A good rib slot cutter might be made from a cut down hacksaw or jigsaw blade with the right width kerf.

All I did today is mark the locations of where the wing needs to seat. I think some modeling clay might help me find the right size and dimensions of the center mounting sheet. I need to go over to SH and search out info on mounting wings in full fuse planes. This is my first.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Oriental ARF assembly

Re: Oriental ARF assembly

While it may be more time consuming, it should be mentioned that gluing one leaf into either or side at a time is highly recommended. Don't try and glue both the flap and also the trailing edge simultaneously. This will allow you even by eye to properly square the hinge leafs as they exit the pieces. It doesn't take much to bind a hinge if it's crooked. Using a small piece of 1/64" ply as a tool to properly spread the epoxy into the hinge pockets you can then use a heat gun to liquify the epoxy allowing it to go further into the pocket. Any excess on top will run into the pocket. Quickly insert the hinges and adjust accordingly. 30 min epoxy is far superior to 15 min. Give yourself enough working time. Ken

Ken Cook- Top Poster

- Posts : 5449

Join date : 2012-03-27

Location : pennsylvania

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Absolutely. I insert them into the flap slots with epoxy, then pull them back out an 8th of an inch or so, wipe any excess glue off with alcohol, and now comes the most important part of aligning them to equal depth.Ken Cook wrote: While it may be more time consuming, it should be mentioned that gluing one leaf into either or side at a time is highly recommended. Don't try and glue both the flap and also the trailing edge simultaneously. This will allow you even by eye to properly square the hinge leafs as they exit the pieces. It doesn't take much to bind a hinge if it's crooked. Using a small piece of 1/64" ply as a tool to properly spread the epoxy into the hinge pockets you can then use a heat gun to liquify the epoxy allowing it to go further into the pocket. Any excess on top will run into the pocket. Quickly insert the hinges and adjust accordingly. 30 min epoxy is far superior to 15 min. Give yourself enough working time. Ken

On my work table I have a thick glass plate with a perfectly straight edge. I hold the flap with all the hinge tabs pointed up and press the hinged edge of the flap against the straight edge, which presses them all in simultaneously to the same depth. You can use any straight edge. A clean door jamb for instance.

Then I place the flap on the edge of the table with the hinges hanging off until the glue hardens. After it's beginning to set firmly, I carefully work each hinge to check for stiffness. If you properly filled the hinge barrels with vaseline, they should be fine.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Oriental ARF assembly

Re: Oriental ARF assembly

It's been so wet and nasty I haven't spent much time on it. But last time we tuned in I was ruminating om how to align the wing despite the improperly placed mounting block which would skew the wing. I have it about figured out and hope to show off something looking like a plane next time I report.

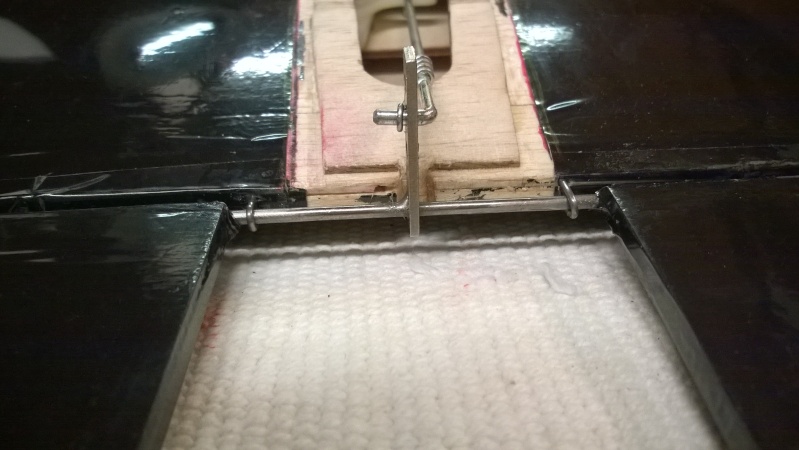

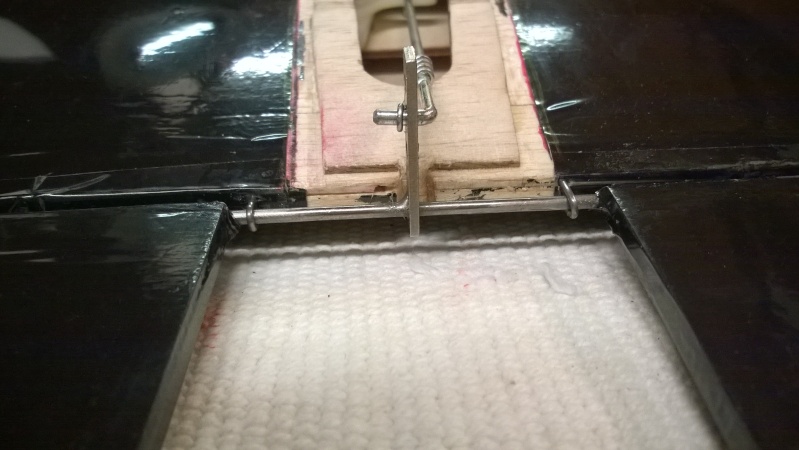

Meanwhile I took some of Ken's advice and made a pair of reinforcing loops of wire for the flap horn. This will help keep the stress on the first hinge on each side in case the horn's rotation is slightly elliptical.

here they are, epoxied into either side of the horn.

Meanwhile I took some of Ken's advice and made a pair of reinforcing loops of wire for the flap horn. This will help keep the stress on the first hinge on each side in case the horn's rotation is slightly elliptical.

here they are, epoxied into either side of the horn.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Rusty, nicely done. You won't regret it as it would stop the flap horn from also flexing resulting in better control. Don't leave the area directly in front of the wire susceptible to oil. Epoxy may be difficult to smear onto it, yellow or white glue would be better than nothing at all. If fuel residue resides along the fuselage side it can find it's way down along side of the fillet and into that area which isn't a good area to have that happen. It can make the wood very spongy there and more than likely make your flap horn retainers pull out. It's a very difficult area to address but anything you can do to help is worth the little effort it takes.

The next problem one is faced with the Oriental is the very low grade wire for the pushrod. My suggestion is not to use it period. You have no way to make a fair lead to support it inside the fuse. A carbon fiber or arrowshaft pushrod is the way to go. However, the holes in the stock flaphorn are metric which usually requires some form of eyelet or bushing in it to allow for the L bend in the fractional music wire. Ken

The next problem one is faced with the Oriental is the very low grade wire for the pushrod. My suggestion is not to use it period. You have no way to make a fair lead to support it inside the fuse. A carbon fiber or arrowshaft pushrod is the way to go. However, the holes in the stock flaphorn are metric which usually requires some form of eyelet or bushing in it to allow for the L bend in the fractional music wire. Ken

Ken Cook- Top Poster

- Posts : 5449

Join date : 2012-03-27

Location : pennsylvania

Re: Oriental ARF assembly

Re: Oriental ARF assembly

I got back to work on it today until the cold concrete floor sucked the life out of me lol. When I start dropping things and misplacing others it's time to quit. I got my pushrod made now.

Then I hooked it to the flap horn and mounted the fuselage on the wing(not glued) to make sure I didn't have any interference, and all seems well. I guess the next step is to put the stab/elevator together. It has the same control horn as the flaps. The short pre-bent rod and spring retainer from the crank fit perfectly on the flap horn, and the flaps have completely frictionless movement.

If you read my post in Ken's Oriental Rework thread, I've been hoping to use a ball link to connect to the elevator horn, but even with the 3/8" spreader installed in the rear of the fuse, there is no room for it. The bolt head, washers and nut would make it too wide. I juggled several options including just using the metric threaded clevis that came with the plane. Or soldering a 4-40 coupling on and using a Sullivan Gold-N-Clevis which has an acceptable rating. I checked and the pin in the Sullivan clevis had just as much slop as the Chinese one. So to hell with it, if it's good enough for John Brodak, it's gonna hafta be good enough for me. Problem swept under the rug. There's nothing in the instructions reminding the builder to adjust for neutral. That's going to be a minor pain... take it off, adjust, put it on, take it off, adjust, put it on, and so on.

Once the stab is built and adjusted I can glue the wing and everything together. As for aligning the wing, I'll use balsa filets on the outside to add to my gluing surface area, since there are some gaps on the inside where I shaved the raised center sheeting to allow for enough twist to get the wing straight. I hope I can get it done as easy as I made that sound. Maybe this weekend.

That's all for now.

Rusty

Then I hooked it to the flap horn and mounted the fuselage on the wing(not glued) to make sure I didn't have any interference, and all seems well. I guess the next step is to put the stab/elevator together. It has the same control horn as the flaps. The short pre-bent rod and spring retainer from the crank fit perfectly on the flap horn, and the flaps have completely frictionless movement.

If you read my post in Ken's Oriental Rework thread, I've been hoping to use a ball link to connect to the elevator horn, but even with the 3/8" spreader installed in the rear of the fuse, there is no room for it. The bolt head, washers and nut would make it too wide. I juggled several options including just using the metric threaded clevis that came with the plane. Or soldering a 4-40 coupling on and using a Sullivan Gold-N-Clevis which has an acceptable rating. I checked and the pin in the Sullivan clevis had just as much slop as the Chinese one. So to hell with it, if it's good enough for John Brodak, it's gonna hafta be good enough for me. Problem swept under the rug. There's nothing in the instructions reminding the builder to adjust for neutral. That's going to be a minor pain... take it off, adjust, put it on, take it off, adjust, put it on, and so on.

Once the stab is built and adjusted I can glue the wing and everything together. As for aligning the wing, I'll use balsa filets on the outside to add to my gluing surface area, since there are some gaps on the inside where I shaved the raised center sheeting to allow for enough twist to get the wing straight. I hope I can get it done as easy as I made that sound. Maybe this weekend.

That's all for now.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Rusty, cut a hole in the side of the fuse and make a access door to get to the clevis. Small wood screws and retain it if you back it up on the inside with small pieces of plywood. Ken

Ken Cook- Top Poster

- Posts : 5449

Join date : 2012-03-27

Location : pennsylvania

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Yes, I'm thinking about that. I hope I can get it close to perfect before I seal it up. I hate to stress the clevis by opening it too many times. I have a jam nut on it, but I wonder if a little solder would be a good idea too... after I know it's right.

For tail weight, I might embed a fat cigar tube with the removable cap outside and fill it with #9 lead shot. From what you and others have written, I'm expecting about 2.5 ounces.

Ken, One question: For ease of routing lines, I would like to slide the tank back from the forward bulkhead an inch. There is plenty of room, but I don't want a long line to make for hard cranking or any other problems. Where do you like to locate your tank? I have the recommended 4oz Brodak tank(BH-559 metal), but if I get one problem with it, I'm switching to the Dubro S-4 clunker. I hope 4oz is enough for the stock 40fp.

Rusty

For tail weight, I might embed a fat cigar tube with the removable cap outside and fill it with #9 lead shot. From what you and others have written, I'm expecting about 2.5 ounces.

Ken, One question: For ease of routing lines, I would like to slide the tank back from the forward bulkhead an inch. There is plenty of room, but I don't want a long line to make for hard cranking or any other problems. Where do you like to locate your tank? I have the recommended 4oz Brodak tank(BH-559 metal), but if I get one problem with it, I'm switching to the Dubro S-4 clunker. I hope 4oz is enough for the stock 40fp.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Rusty, I wouldn't solder it. I prefer the Sullivan clevis due to them using a locking clip. They can be a pain in the rear to put on, but they keep the clevis from popping off. Dubro uses the heavy plastic that slides up and over the halves which works well. I think the heat can certainly have an impact on the spring steel not to mention your not adjusting it afterwards. I think it could cause a problem which is why I just wouldn't do it unless it was specifically a solder link clevis.

As for the fuel tank, I had a metal tank ATF (All tubes forward) in the tank compartment. I had the front of the tank essentially 1/4" from the firewall. The Dubro S-4 I'm currently using is set back a bit due to the plumbing arrangement I have. With the metal tank, I had my overflow in hard pipe directly down the front of the firewall behind the engine. I used small U shaped pins made from music wire essentially the same way you secured your flap horn. This held the piece of copper I used which was about 1 1/2" long with a L bend going through the firewall and into the compartment. I used a small piece of tubing as a coupler. The plastic tank was a bit more difficult to work with. I set it back a little more than 1". I basically try and get it as close as possible to keep the fuel lines the shortest. I also use a H&R fuel filter which is very small about the size of a pencil eraser just outside of the firewall prior to the fuel line taking a 90 deg bend into the spraybar. It's been too cold to test the Dubro I was using. I was getting burn down lean screaming runs. I since did some modifications. I switched out the clunk for a sintered clunk. I also switched to a 2 line system where the pickup and also the uniflow are independent. I had a soldered hitchiker setup prior to where my feed and uniflow were linked together by a Y pipe at the clunk. I can provide pictures.

The FP 40 can be a funny one. It also depends on your version, iron version or ABN. I'm not saying 4 oz's isn't impossible, there are many factors at work. Prop size, plane weight, venturi size, muffler and nitro are all factors. I use 5% nitro with the FP. It can yield approx 2.5 laps over 10% nitro. Dennis the Philly Fliers FP expert has always used the FP and the Tower .40 since I've been with him close to 15 years now. He uses venturi sizes here in the .265"-.272" range. Many use the smaller venturi's to increase fuel economy. I found this to overheat the engine severely and offer a useless amount of power. We like to use the APC 10.5 x 4.5 prop which works very well for us here. The THunder Tiger I sent you is a prop I like to use on the FP due to a bit more blade area. It really comes down to trying it and see what happens. If things go well, no runaway will take place. The FP is however notorious for the runaway. Adding a head gasket or two will help many issues including giving you more fuel economy. It lowers the compression which reduces the power but you can lean the needle in to get back to the same power you once were prior to the gaskets. This will increase your fuel mileage substantially. The main thing is to not trigger the engine into runaway by getting it hot. Let it run where it wants to. This is why the APC with little blade area works well. It still provides decent thrust but doesn't overheat the engine by loading it. Ken

As for the fuel tank, I had a metal tank ATF (All tubes forward) in the tank compartment. I had the front of the tank essentially 1/4" from the firewall. The Dubro S-4 I'm currently using is set back a bit due to the plumbing arrangement I have. With the metal tank, I had my overflow in hard pipe directly down the front of the firewall behind the engine. I used small U shaped pins made from music wire essentially the same way you secured your flap horn. This held the piece of copper I used which was about 1 1/2" long with a L bend going through the firewall and into the compartment. I used a small piece of tubing as a coupler. The plastic tank was a bit more difficult to work with. I set it back a little more than 1". I basically try and get it as close as possible to keep the fuel lines the shortest. I also use a H&R fuel filter which is very small about the size of a pencil eraser just outside of the firewall prior to the fuel line taking a 90 deg bend into the spraybar. It's been too cold to test the Dubro I was using. I was getting burn down lean screaming runs. I since did some modifications. I switched out the clunk for a sintered clunk. I also switched to a 2 line system where the pickup and also the uniflow are independent. I had a soldered hitchiker setup prior to where my feed and uniflow were linked together by a Y pipe at the clunk. I can provide pictures.

The FP 40 can be a funny one. It also depends on your version, iron version or ABN. I'm not saying 4 oz's isn't impossible, there are many factors at work. Prop size, plane weight, venturi size, muffler and nitro are all factors. I use 5% nitro with the FP. It can yield approx 2.5 laps over 10% nitro. Dennis the Philly Fliers FP expert has always used the FP and the Tower .40 since I've been with him close to 15 years now. He uses venturi sizes here in the .265"-.272" range. Many use the smaller venturi's to increase fuel economy. I found this to overheat the engine severely and offer a useless amount of power. We like to use the APC 10.5 x 4.5 prop which works very well for us here. The THunder Tiger I sent you is a prop I like to use on the FP due to a bit more blade area. It really comes down to trying it and see what happens. If things go well, no runaway will take place. The FP is however notorious for the runaway. Adding a head gasket or two will help many issues including giving you more fuel economy. It lowers the compression which reduces the power but you can lean the needle in to get back to the same power you once were prior to the gaskets. This will increase your fuel mileage substantially. The main thing is to not trigger the engine into runaway by getting it hot. Let it run where it wants to. This is why the APC with little blade area works well. It still provides decent thrust but doesn't overheat the engine by loading it. Ken

Ken Cook- Top Poster

- Posts : 5449

Join date : 2012-03-27

Location : pennsylvania

Re: Oriental ARF assembly

Re: Oriental ARF assembly

The elevator/stab are assembled. I decided to save some time and use the CA hinges. I hope I don't regret it. I took one of my un-needed hinges and put a drop of my Loctite CA on it. It's not labeled thin or thick, and I wanted to see it spread across the surface, but it just sat there. So at the grocery store today I bought a tube of Krazy Glue that was not marked "Gel" but not marked thin either. It didn't spread much better, but I went ahead and used it. The hinges seem like they're stuck in there pretty good, but I'll do a pull test tomorrow. They are stiffer than I expected. I hope I don't regret this, but if I do, it's easy enough to cut apart and put some real hinges in.

Next the fuse and wing will be joined, as will the stab. It should look like a plane soon now. For the fuselage/wing joint I bought some Gorilla glue. That should swell up and fill the vertical gaps where the saddle and the wing's contour don't match, and also the horizontal gaps between the internal fuse sides at the alignment block, where I removed some wood.

I've never used Gorilla glue before, so I have some test practice pieces setting up tonight. I intentionally left some gaps and i can already tell they are more than full. This stuff really grows. It's the newer white Gorilla glue, but all the literature indicates it's the same as the old brown stuff. I might mix a little sawdust in a couple of spots. I will probably use some epoxy right at the LE and TE joints. And nothing but epoxy on the bottom cap of the wing. Eventually it will get an epoxy/Microballoon filets top and bottom. I wouldn't bother with that if I hadn't had the alignment problem.

So we'll see how that ambitious plan works out. Or maybe tomorrow I'll just fire up a couple of Tach Racers and slouch around the house. I'll probably get some of the above done. See y'all in the funny papers.

Rusty

Next the fuse and wing will be joined, as will the stab. It should look like a plane soon now. For the fuselage/wing joint I bought some Gorilla glue. That should swell up and fill the vertical gaps where the saddle and the wing's contour don't match, and also the horizontal gaps between the internal fuse sides at the alignment block, where I removed some wood.

I've never used Gorilla glue before, so I have some test practice pieces setting up tonight. I intentionally left some gaps and i can already tell they are more than full. This stuff really grows. It's the newer white Gorilla glue, but all the literature indicates it's the same as the old brown stuff. I might mix a little sawdust in a couple of spots. I will probably use some epoxy right at the LE and TE joints. And nothing but epoxy on the bottom cap of the wing. Eventually it will get an epoxy/Microballoon filets top and bottom. I wouldn't bother with that if I hadn't had the alignment problem.

So we'll see how that ambitious plan works out. Or maybe tomorrow I'll just fire up a couple of Tach Racers and slouch around the house. I'll probably get some of the above done. See y'all in the funny papers.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Oriental ARF assembly

Re: Oriental ARF assembly

CA hinges...

Lot's of opinions out there on those. I think for large models they are OK. Sometimes a little stiff for CL use, but I find if you work the hinges back and forth after gluing they free up nicely.

One real problem I see is if you plow the model in. The elevator gets thrown forward and the hinges take the stab with it.

Other than that, they work well enough.

Lot's of opinions out there on those. I think for large models they are OK. Sometimes a little stiff for CL use, but I find if you work the hinges back and forth after gluing they free up nicely.

One real problem I see is if you plow the model in. The elevator gets thrown forward and the hinges take the stab with it.

Other than that, they work well enough.

Cribbs74- Moderator

Posts : 11895

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Plowing it in, yeah. I'm still upset over plowing two planes in three weeks back in the Fall.

I just took a break from writing this and went to check on my Gorilla glue test, and Damn, I have a new favorite glue! I know it's really heavy, but my tests were amazing. Gaps filled like crazy. I can bridge all the areas in the wing I was worried about. After only a couple of hours of curing, I broke one 90 degree 3"x1/8" balsa joint, hard Sterling balsa, and only wood broke. And the two sticks I glued face to face with parallel grain took some serious strength to break. And that was just a thin smear between them.

I got so excited I jigged my wing and drew the reference lines on the sheeting to align the fuse. I'm definitely gluing it in the morning. The stab will be ready to install as soon as I can get to it.

Rusty

I just took a break from writing this and went to check on my Gorilla glue test, and Damn, I have a new favorite glue! I know it's really heavy, but my tests were amazing. Gaps filled like crazy. I can bridge all the areas in the wing I was worried about. After only a couple of hours of curing, I broke one 90 degree 3"x1/8" balsa joint, hard Sterling balsa, and only wood broke. And the two sticks I glued face to face with parallel grain took some serious strength to break. And that was just a thin smear between them.

I got so excited I jigged my wing and drew the reference lines on the sheeting to align the fuse. I'm definitely gluing it in the morning. The stab will be ready to install as soon as I can get to it.

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Rusty, I really can't comment on the CA hinges. If your into refining a pattern, smoothness of controls is essential. The flaps should fall on their own weight and that more than likely isn't going to happen. Many times when a plane hunts up and down in level flight it's due to sticky or binding control surfaces. I can see them being very problematic especially when you exit out of the reverse wing over. This will certainly cause the plane to jump due to your wrist trying to compensate for those hinges. I've seen those hinges fail many times due to ca saturation which causes a hard point within them. Ken

Ken Cook- Top Poster

- Posts : 5449

Join date : 2012-03-27

Location : pennsylvania

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Had to look it up but I have some of these hinges and they are very stiff , I have never used them and don't think I would on CL I think they are more for RC use as you would have a servo control. To save time now when building is not always a good work out in the end and cost more time to take apart and redo when you are wanting to fly . Just my  Eric

Eric

Eric

Eric

getback- Top Poster

Posts : 10114

Join date : 2013-01-18

Age : 66

Location : julian , NC

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Ah shoot, that doesn't sound good. After I finish the plane, I'll slice them and sew some hinges in.

Rusty

Rusty

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Oriental ARF assembly

Re: Oriental ARF assembly

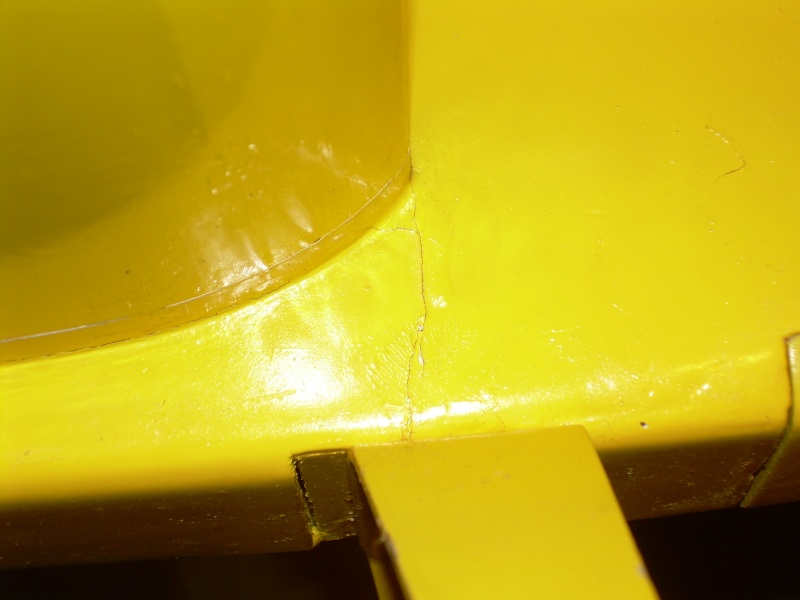

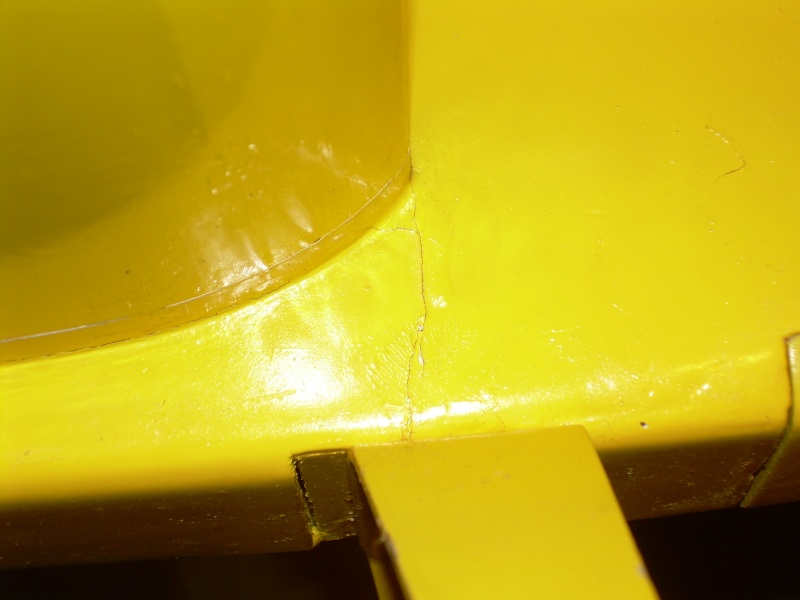

Rusty, here's a few pics of what I've been describing in terms of problem joints or ones that quickly fatigue. Also, while not in chronological order, I can provide some details to the Oriental's I've built.

This is ARF #2 with weight box installed for CG issues. While not deep enough to house all the weight entirely, a few things were done to assist. I made the top block over the stab from poplar which added a few grams of assistance. I was also able to glue some smashed 1/4 oz weights internally before gluing in the box. Note the stab reinforcing blocks to support the punky wood provided with the stock kit. The wood is actually too light for this use and the end result is typically failure due to scoring the covering to glue it in properly. Mine broke in flight due to it bumping my launcher's leg upon release.

This is underside shot of the Oriental showing the sheeting which was glued internally. The way the fuse was glued was via the canopy. Top block molded sheeting was removed, 1/4" x 1/4" balsa was laid internally against inside walls of fuse.

ARF #1 showing clevis access door permanently attached once model was trimmed. No stab reinforcing blocks on side of fuse. This resulted in elevator failure as mentioned above which couldn't be adequately fixed at the field. I slipped 1/64" ply over the top and through the fuse and used fiberglass over top smoothed and sanded. This plane has many issues such as sloppy controls due to the inferior control system supplied. I learned quickly that using the stock parts was a HUGE mistake. This plane is very heavy currently. This is due to oil soaking and repairs. This beast is nearing 50 oz's. This is mostly due to oil soaking. Flies great in the wind however but it feels like your flying a .60 size stunter. I should also mention this is painted with Rustoleum due to covering exiting body and wing during flight.

ARF #1 showing the dreaded fuse break which occurs. I mentioned this numerous times. This developed within the first few flights. I really didn't know how to address it at the time aside from pouring CA continuously. ARF #3 has 1/64" ply biscuits backing up the joints and is fiberglassed on the outside.

This is ARF #2 with weight box installed for CG issues. While not deep enough to house all the weight entirely, a few things were done to assist. I made the top block over the stab from poplar which added a few grams of assistance. I was also able to glue some smashed 1/4 oz weights internally before gluing in the box. Note the stab reinforcing blocks to support the punky wood provided with the stock kit. The wood is actually too light for this use and the end result is typically failure due to scoring the covering to glue it in properly. Mine broke in flight due to it bumping my launcher's leg upon release.

This is underside shot of the Oriental showing the sheeting which was glued internally. The way the fuse was glued was via the canopy. Top block molded sheeting was removed, 1/4" x 1/4" balsa was laid internally against inside walls of fuse.

ARF #1 showing clevis access door permanently attached once model was trimmed. No stab reinforcing blocks on side of fuse. This resulted in elevator failure as mentioned above which couldn't be adequately fixed at the field. I slipped 1/64" ply over the top and through the fuse and used fiberglass over top smoothed and sanded. This plane has many issues such as sloppy controls due to the inferior control system supplied. I learned quickly that using the stock parts was a HUGE mistake. This plane is very heavy currently. This is due to oil soaking and repairs. This beast is nearing 50 oz's. This is mostly due to oil soaking. Flies great in the wind however but it feels like your flying a .60 size stunter. I should also mention this is painted with Rustoleum due to covering exiting body and wing during flight.

ARF #1 showing the dreaded fuse break which occurs. I mentioned this numerous times. This developed within the first few flights. I really didn't know how to address it at the time aside from pouring CA continuously. ARF #3 has 1/64" ply biscuits backing up the joints and is fiberglassed on the outside.

Ken Cook- Top Poster

- Posts : 5449

Join date : 2012-03-27

Location : pennsylvania

Re: Oriental ARF assembly

Re: Oriental ARF assembly

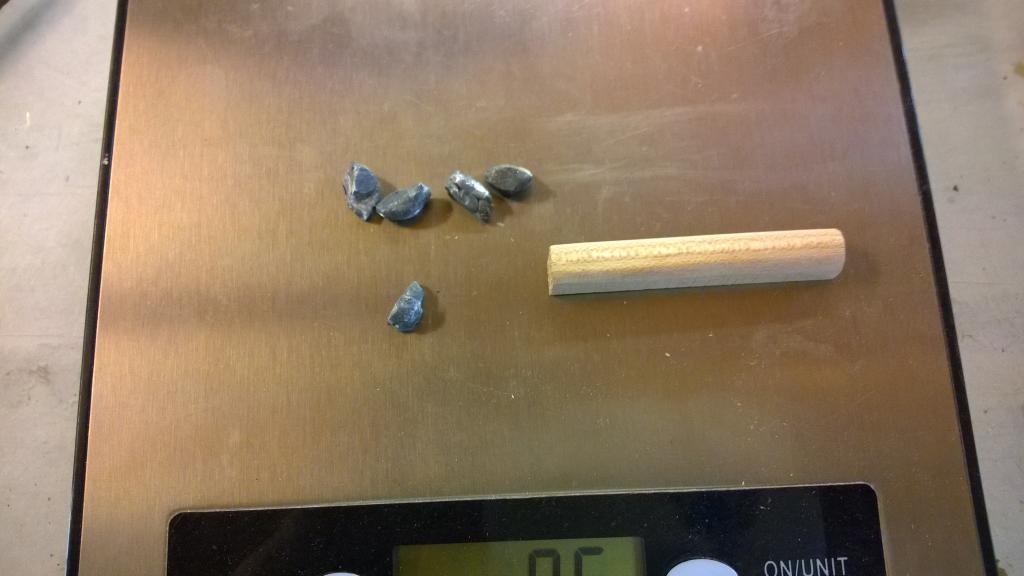

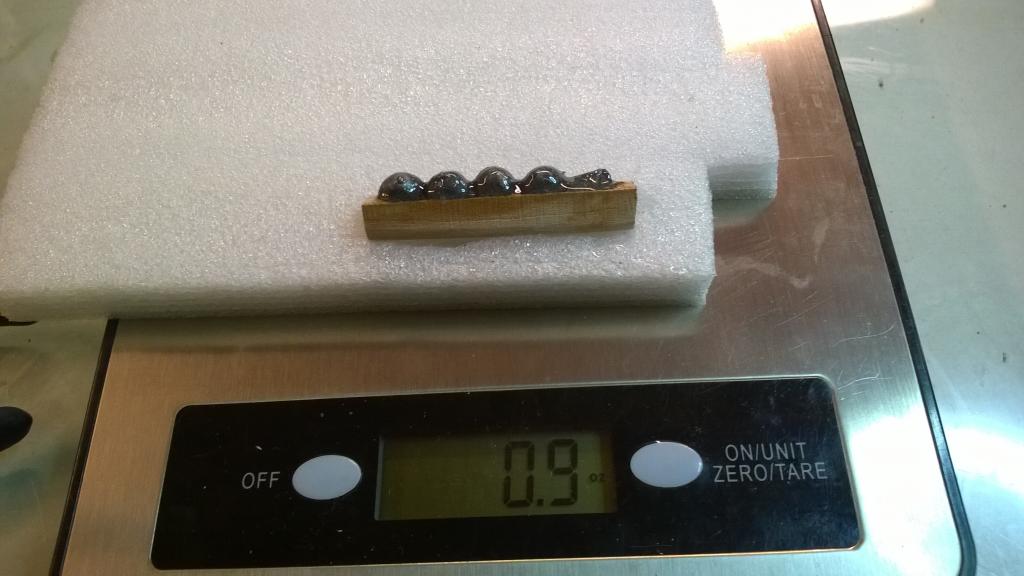

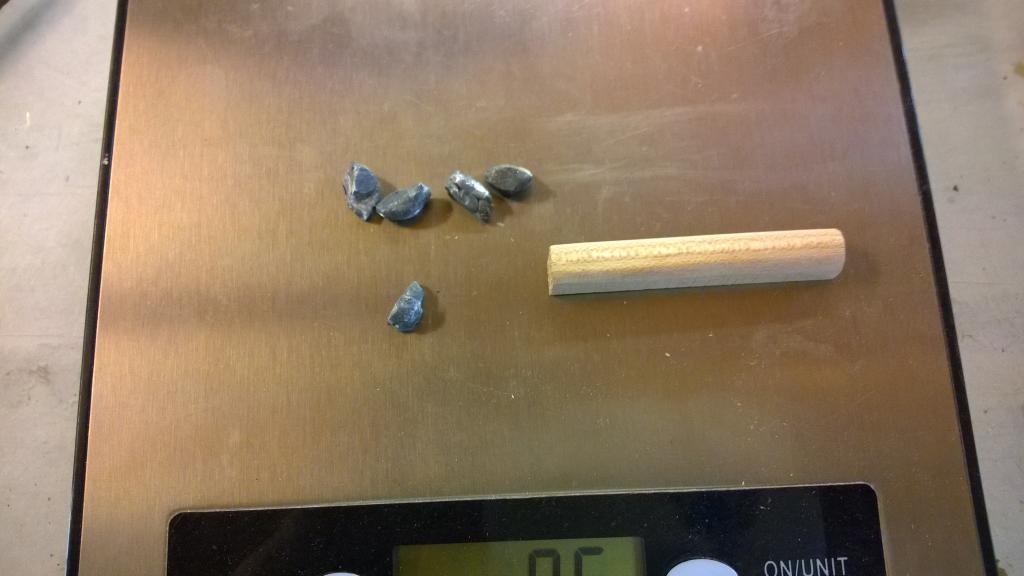

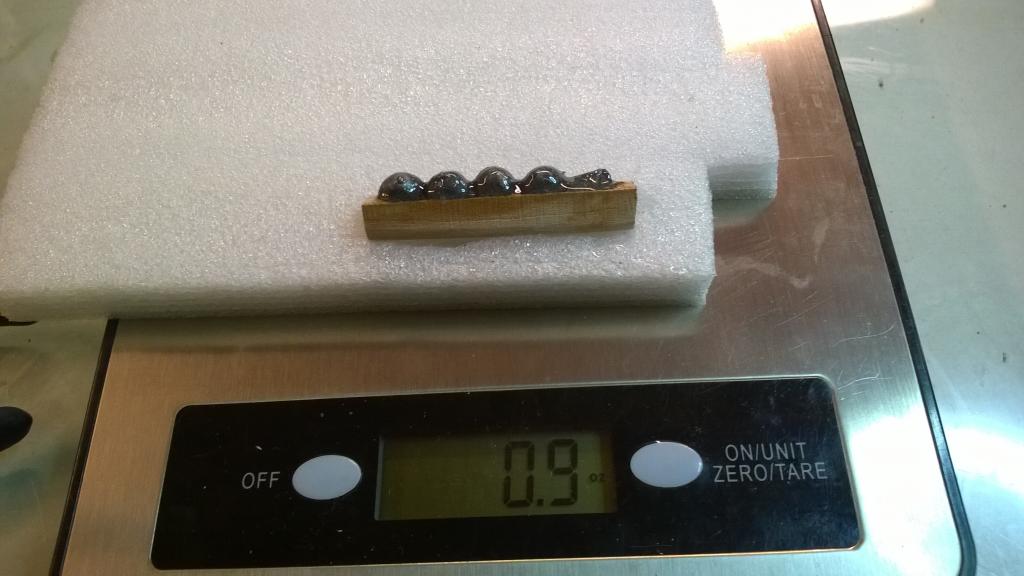

Finally got something to show. First, since I had to make a block to spread the tail end so there is enough room for fiddling with the elevator linkage, and make room for adjusting weight, I decided to make it functional.

I cut it from a Poplar square dowel, rounded one side and added weight to it. That's a good place for lead since it's far back and has the best leverage. Then hollowed it out and smashed some split shot from my tackle box into shape. I had it all fixed up so it would weigh exactly 1oz. and(I'm glad y'all can't see me work sometimes) flailed around or something, and knocked the damn thing off the table. I couldn't find one of the whole shot. I had cut a bunch in half, another dumb move. So it weighs .9oz. What a maroon.

I am so sick of talking about that wing. Today I glued it in place. For new readers who may have missed it, the ARF's raised strip on the center sheeting was not in line with the fuselage center. This is what aligns and holds the fuselage perpendicular to the wing. This crooked one created all sorts of thinking, asking, and experimenting, and worrying a lot about strength. This is why I opted for the original expanding Gorilla Glue. It's very strong and fills gaps. It looks like the strength distributed across the gaps is a somewhat less than epoxy, but its gap filling ability absolutely outweighed epoxy. My test joints were simply incredible. One of the things I tried was gluing two strips of flat 1/8" balsa together with parallel grain. The next day, after slicing 3/8" of hard foam from the sides(you don't need very much glue), I had to try really really hard to break it in half. It had soaked in and taken over the wood. You must practice several times before using it.

So, here is the wing glued to the fuselage with a straight and square redneck jig and weights holding it in place. I was intentionally a bit heavy handed with the glue. I'd love to see inside, but hopefully I never will. I put vaseline on the flap horn. I added some more wood on the wing. All of it is CAd in place, but I made sure not to let it absorb enough to render it ineffective. Note where I cut back the yellow Monokote to leave room for an epoxy/Microballoon filet. First I will put a small plain epoxy bead along the root. After it hardens I'll build it up with as little filler as I can get away with and still look good. I wonder what would happen if I put some yellow paint in it. Ideas are welcome. Enough blabbing, here're the pics.

I cut it from a Poplar square dowel, rounded one side and added weight to it. That's a good place for lead since it's far back and has the best leverage. Then hollowed it out and smashed some split shot from my tackle box into shape. I had it all fixed up so it would weigh exactly 1oz. and(I'm glad y'all can't see me work sometimes) flailed around or something, and knocked the damn thing off the table. I couldn't find one of the whole shot. I had cut a bunch in half, another dumb move. So it weighs .9oz. What a maroon.

I am so sick of talking about that wing. Today I glued it in place. For new readers who may have missed it, the ARF's raised strip on the center sheeting was not in line with the fuselage center. This is what aligns and holds the fuselage perpendicular to the wing. This crooked one created all sorts of thinking, asking, and experimenting, and worrying a lot about strength. This is why I opted for the original expanding Gorilla Glue. It's very strong and fills gaps. It looks like the strength distributed across the gaps is a somewhat less than epoxy, but its gap filling ability absolutely outweighed epoxy. My test joints were simply incredible. One of the things I tried was gluing two strips of flat 1/8" balsa together with parallel grain. The next day, after slicing 3/8" of hard foam from the sides(you don't need very much glue), I had to try really really hard to break it in half. It had soaked in and taken over the wood. You must practice several times before using it.

So, here is the wing glued to the fuselage with a straight and square redneck jig and weights holding it in place. I was intentionally a bit heavy handed with the glue. I'd love to see inside, but hopefully I never will. I put vaseline on the flap horn. I added some more wood on the wing. All of it is CAd in place, but I made sure not to let it absorb enough to render it ineffective. Note where I cut back the yellow Monokote to leave room for an epoxy/Microballoon filet. First I will put a small plain epoxy bead along the root. After it hardens I'll build it up with as little filler as I can get away with and still look good. I wonder what would happen if I put some yellow paint in it. Ideas are welcome. Enough blabbing, here're the pics.

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Rusty, when you mix your epoxy and micro balloons go easy on the powder as it will keep the strength in the epoxy and not cause it to shatter when subjected to flex. Mix a little a time and work it onto your fuse a little at a time. Painting modified epoxy requires you to clean the epoxy fillet with some acetone. Wrapping a small dowel with a piece of sandpaper glued to it allows for you to sand the radius and open up the top layer. Cleaning this with acetone or thinner will allow for paint to properly stick to it. It must be sanded and all waxy like residue needs to be removed prior to painting. Welcome to the wonderful world of ARF's.

Ken Cook- Top Poster

- Posts : 5449

Join date : 2012-03-27

Location : pennsylvania

Re: Oriental ARF assembly

Re: Oriental ARF assembly

The bottom cap didn't fit quite right. It was too short from front to back so the end plates didn't quite mate. A 1/32" sheet of balsa perfected the end to end fit, but ruined the fit at the saddle. Without the shim, the saddle hugged the wing nicely, only the belly of the plane has a slight indention where the cap sits a tiny bit below the rest of the fuselage. So, to hell with it, purely cosmetic, it's an ARF. I added some balsa dust to the glue and clamped it in place. Later it srt up with a perfect joint along the root amd, I presume, a great fit at each end plate. I hope to never see the insides again Lol.

I spent a while trying to decide if I have more flap deflection than elevator. Hard to tell, looks about 1:1.

I also checked the elevator deflection. It's equal in both directions, I hope it's enough.

Full Down

Full Up

I spent a while trying to decide if I have more flap deflection than elevator. Hard to tell, looks about 1:1.

I also checked the elevator deflection. It's equal in both directions, I hope it's enough.

Full Down

Full Up

_________________

Don't Panic!

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

...and never Ever think about how good you are at something...

while you're doing it!

My Hot Rock & Blues Playlist

RknRusty- Rest In Peace

- Posts : 10869

Join date : 2011-08-10

Age : 68

Location : South Carolina, USA

Re: Oriental ARF assembly

Re: Oriental ARF assembly

Looks like more than enough. I don't remember the big steel flounder.

Cribbs74- Moderator

Posts : 11895

Join date : 2011-10-24

Age : 50

Location : Tuttle, OK

Page 2 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Similar topics

Similar topics» 1/2A Nobler & 1/2A Oriental - foam wings, profile

» Skitzoid Phred here with Brodak ARC Oriental addition to the growing fleet

» Another Oriental shakedown flight

» My Oriental's OS 40fp spraybar

» First patterns with the Oriental - Video

» Skitzoid Phred here with Brodak ARC Oriental addition to the growing fleet

» Another Oriental shakedown flight

» My Oriental's OS 40fp spraybar

» First patterns with the Oriental - Video

Page 2 of 5

Permissions in this forum:

You cannot reply to topics in this forum

Rules

Rules